class ii division 2 hazardous locations

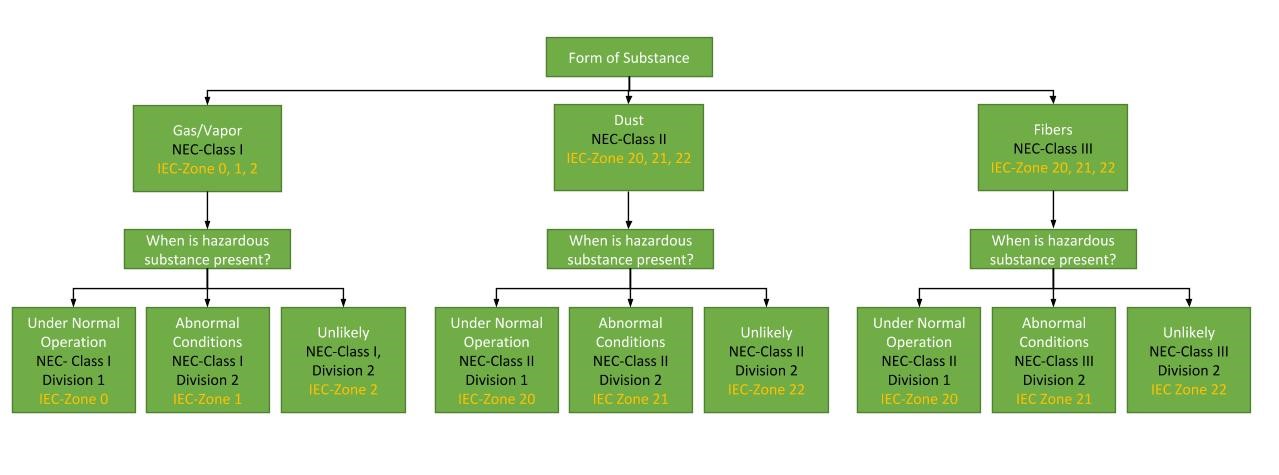

These hazardous classified locations are assigned six designations as follows. Small combustible dust particles can burn easily and ra.

1910 307 Hazardous Classified Locations Occupational Safety And Health Administration

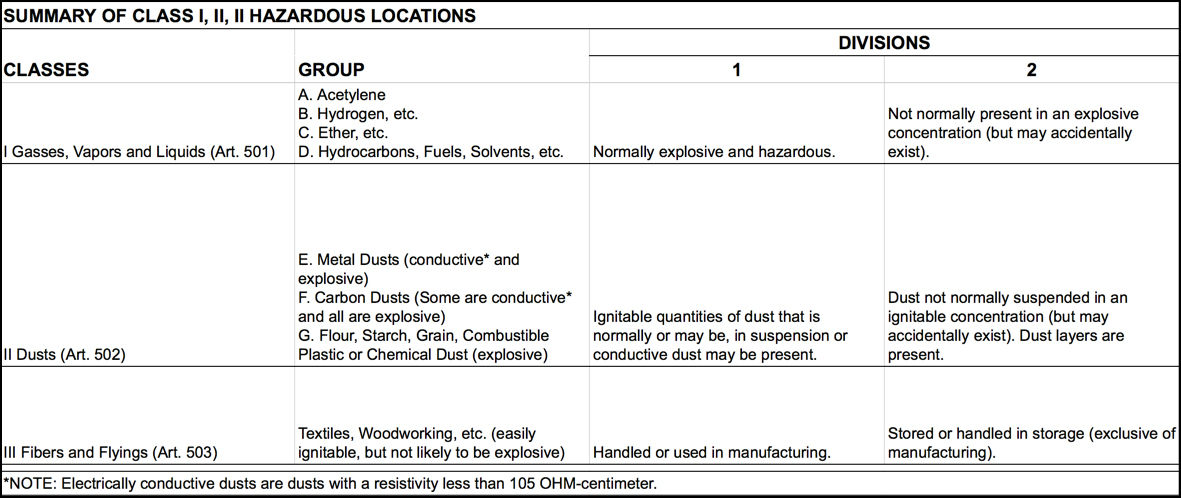

Locations that are hazardous because of the presence of combustible dust.

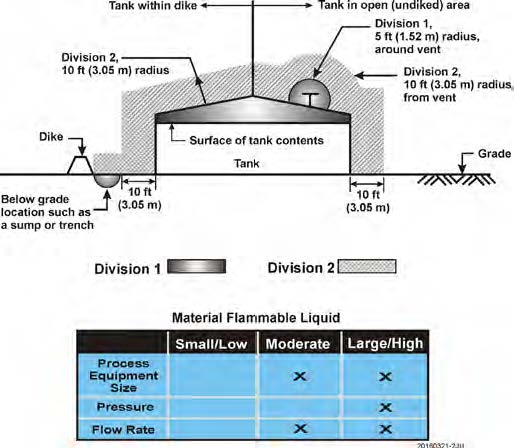

. Class II Division 2 is where the dust material is stored or handled other than in the process of manufacturing. A Class 1 location means that the location has presence of explosive and or flammable mixtures of vapors or gases. Class 2 Division 21 C.

Note that the dust must be present in sufficient quantities for a fire or explosion hazard to exist. Class II locations include the following. Class I Division 1 Class I Division 2 Class II Division 1 Class II Division 2 Class III Division 1 Class III Division 2.

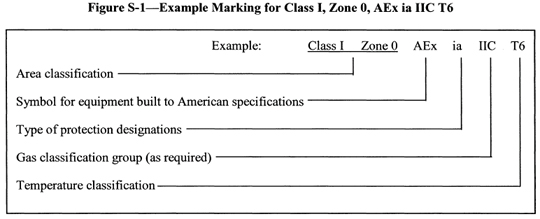

According To ISA-121201. DIVISION OF SOLID AND HAZARDOUS WASTE CONSUMER ELEC T RONICS RECYCLING FACILITIES Updated April 2020. Class 1 Division 11 B.

Class 3 Division 32 D. Class I Division 2. Class II Division 1 is in an area where dust material is handled manufactured or used.

Articles 500 through 504 cover the requirements for electrical and electronic equipment and wiring for all voltages in Class I Divisions 1 and 2. In both divisions it is important to protect your electrical systems from these. Dust explosive atmospheres are hazardous due to the presence of combustible dusts fibres or flyings.

Just as in Class I Division 1 and 2 the subdivision of Class II into Divisions 1 and 2 identifies the likelihood that there will be an explosion hazard. Class II locations are those that are hazardous because of the presence of combustible dust. 5001 Scope Articles 500 Through 504.

Class II Division 2. 1 Class II Division 1. NEC and UL segregate this hazardous location into two divisions.

The Division 1 signifies that these hazardous gas or vapor air mixtures are. For definitions of these locations see 1926. An MC 306 non-pressure liquid carrier easily identified by its polished aluminum color and its.

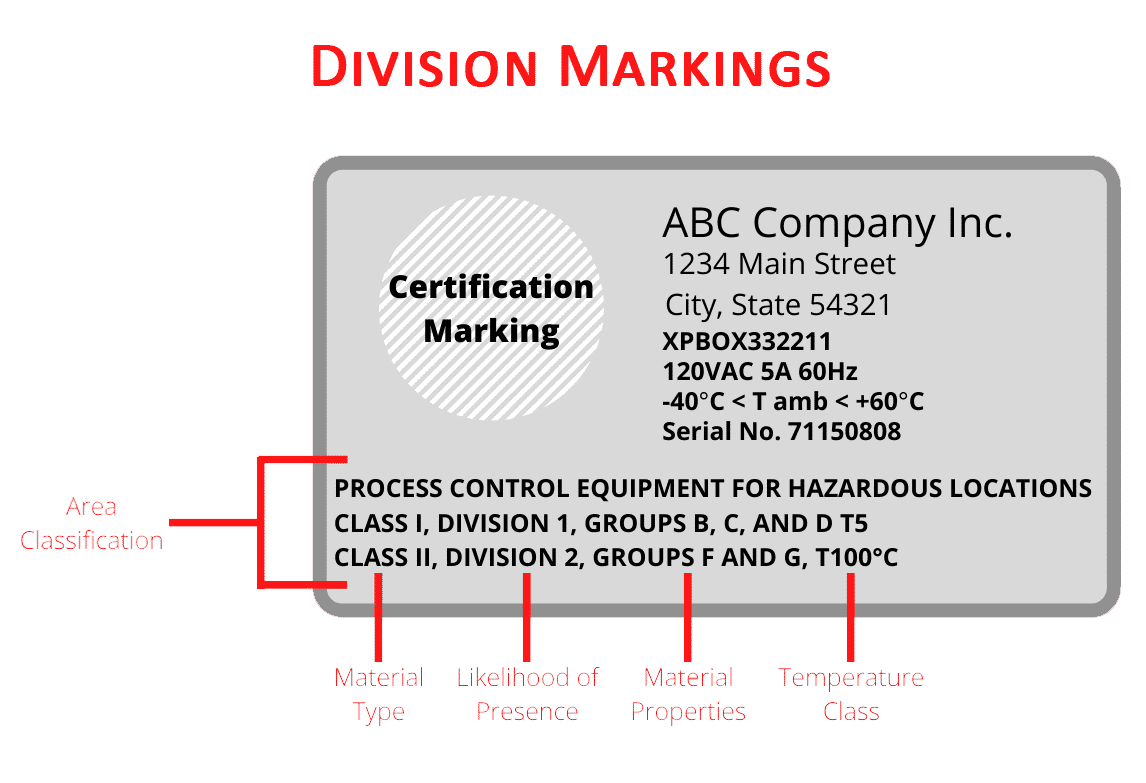

The purpose of this standard is to provide minimum requirements for the design construction and marking of electrical. Class I Division 1. The assessment for nonincendive equipment for Class II and III Division 2 locations differs in that it focusses primarily on keeping the hazardous dust atmosphere from.

Class 4 Division 43 9. These facilities are approved to demanufacture. A Class II Division 1 location is.

Each room section or area shall be considered individually in determining its classification.

100 Watt Led Hazardous Location Light Class I Div Ii Appro

Hazardous Area Classification Process Safety Fauske

Hazardous Area Classifications What You Need To Know Precision Digital

Electrical Equipment In Hazardous Areas Wikipedia

T Class Ratings Temperature Ratings Hazardous Area T Class Ratings

Class I Division 2 Class I Zone 2 Class Ii Division 2 Or Zone 22 Locations Upcodes

Hazardous Locations Products Archives Thermal Edge

Larson Electronics Class I Div Ii Bug Eyes Emergency Lighting System Hazardous Locations Exit Sign 120 277v

Gas Bottle Heating Jacket For C1 D2 Hazardous Locations

Hazardous Locations Groups Classes And Divisions Valveman Com

Hazardous Location Testing Certification Hazloc Product Testing F2 Labs

Maxlite Hl Li2440u Hazardous Location Linear Light 40w 2

Advantech S Oil Gas Solutions Cid2 Certification

Explanation Of Hazardous Locations Class Ii Div 1 Groups E F And G

Hazardous Location Classification

Ul Class 1 Div 2 Certified Products What Is Class 1 Div 2 Class I Ii Iii Hazardous Locations Us Department Of Labor Osha Office Of Training And Ppt Download

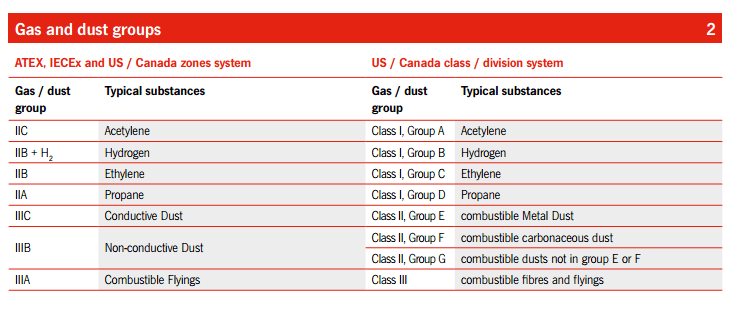

Hazardous Area Charts Class Div Zone Atex Iecex Anderson Controls